Key Points:

- Master TPO roof puncture repair by identifying damage correctly, using proper materials, and following step-by-step techniques to effectively prevent water damage.

- Avoid common repair mistakes and recognize when professional expertise is crucial for complex TPO roof damage compared to simple DIY fixes.

- Conduct regular inspections and use protective measures to prevent future TPO roof punctures and prolong your single-ply roofing system’s lifespan.

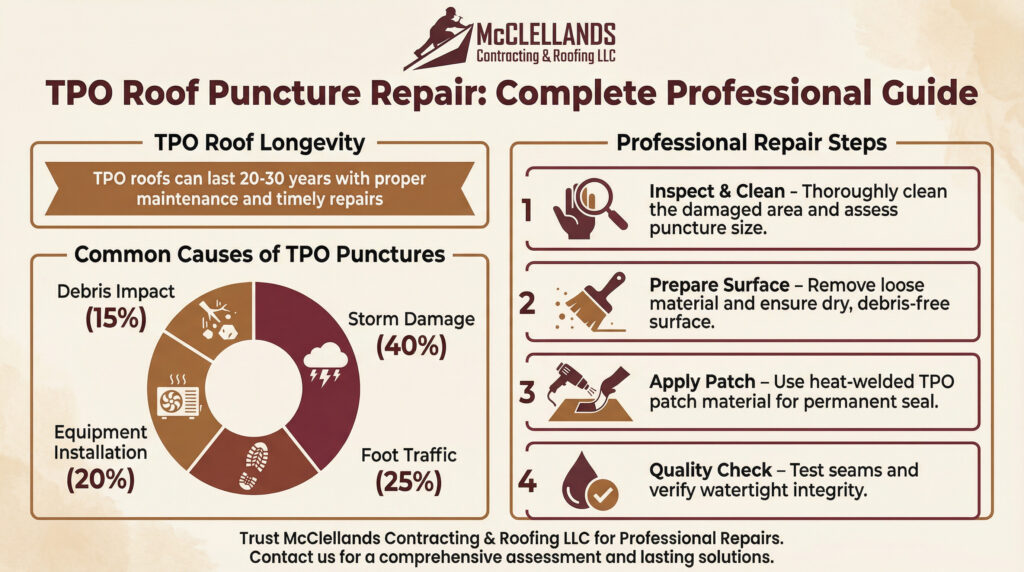

TPO roof punctures are a serious threat to commercial buildings, potentially leading to expensive water damage and structural issues if they’re left unaddressed. These punctures can result from various sources, including hail, falling debris, foot traffic, or equipment installation. Property owners and facility managers need to understand how to properly identify puncture damage early and assess its severity to prevent minor issues from escalating into major roofing problems.

Recognizing the signs of TPO membrane damage requires knowing both the visible indicators on the roof’s surface, along with interior signs that suggest water infiltration. The inspection process determines whether simple TPO roof patching techniques will be enough or if more complicated repair methods are needed. Understanding the difference between surface-level damage and deeper cuts into the roof itself helps property owners make informed decisions about repair strategies and prevents unnecessary commercial roof leak repair expenses down the road.

The Tools and Materials Needed to Effectively Repair TPO Punctures

Successful TPO membrane repair requires specific professional-grade materials designed for single-ply roofing systems. The primary components include TPO membrane patches that match the existing roof material, specialized primers that ensure proper adhesion, and high-strength adhesives formulated specifically for thermoplastic applications. Quality repair materials also encompass cleaning solvents, seam sealers, and reinforcement fabrics for larger punctures requiring comprehensive TPO roof patching solutions.

Proper surface preparation and application demand specialized tools beyond standard construction equipment. Essential items include hot air welding guns for thermoplastic bonding, pressure rollers for achieving uniform adhesion, and infrared thermometers to monitor application temperatures. Additional equipment that can be used includes utility knives with fresh blades, measuring tools for accurate patch sizing, and cleaning brushes for debris removal. Weather-resistant storage containers protect materials from moisture and temperature fluctuations during commercial roof leak repair projects, ensuring optimal performance regardless of environmental conditions during the TPO seam repair process.

| Tool/Material | Purpose | Specifications |

| Hot Air Welding Gun | Thermoplastic bonding | Professional-grade for TPO material |

| Pressure Rollers | Achieve uniform adhesion | Various sizes for different patch areas |

| Infrared Thermometer | Monitor application temperatures | Accurate temperature readings critical for proper bonding |

| Utility Knives | Cutting and trimming | Fresh, sharp blades required |

| Measuring Tools | Accurate patch sizing | Tape measure, straight edge, marking tools |

| Cleaning Brushes | Debris removal | Stiff bristles for thorough surface prep |

The Process for Handling Small TPO Roof Puncture Repairs

Preparing the surface of the roof is a foundational step for successful TPO roof patching, and it begins with thoroughly cleaning the damaged area. The punctured section requires debris, dirt, and any loose membrane material to be completely removed using appropriate cleaning solutions. Priming the surface properly ensures that any material will adhere well between the existing TPO membrane and repair materials. The primer must cure completely before patch application, creating the chemical bond necessary for long-term single-ply roof repair performance.

Installing a patch requires precise sizing and positioning to achieve effective TPO membrane repair. The patching material should extend at least 3 inches beyond the puncture in all directions, providing enough overlap for secure bonding. Hot air welding forms the bond between the patch and the membrane, requiring consistent temperature control throughout the application process.

Proper sealing techniques involve applying uniform pressure while the weld cools, preventing air pockets that could compromise the repair. Final seam sealing around the patch perimeter completes the commercial roof leak repair process, creating a watertight barrier that prevents future infiltration at the TPO seam repair location.

Keep in mind that while a heat welder can be used by DIYers, it’s still a complicated tool that takes practice to use correctly. If necessary, hire a professional who has experience with these tools.

Advanced Repair Techniques for Large or Multiple Punctures

Extensive TPO membrane damage requires sophisticated repair approaches that go beyond standard patching methods. Large punctures or multiple damaged areas often require cutting out the compromised sections entirely and installing larger pieces of membrane using advanced bonding techniques. Heat welding becomes critical for these complex TPO roof puncture repair scenarios, as it creates seamless bonds that match the original membrane’s structural integrity.

Chemical bonding agents could be used to supplement welding processes when weather conditions or membrane positioning make traditional heat application challenging. This should always be a temporary measure, and more permanent solutions will be necessary in the future.

Punctures occurring near critical structural elements demand special attention due to the increased risk of leaks and system failure. Areas surrounding penetrations, equipment attachments, and existing seams require modified repair strategies that account for points of structural stress and thermal movement. TPO seam repair near these vulnerable zones often involves reinforcement materials and multi-layer application techniques to ensure long-term performance.

During the repair process, temporary waterproofing measures may be needed to prevent ongoing damage while comprehensive TPO membrane repair work progresses through multiple phases of installation and curing.

Common Mistakes That Lead to Failed TPO Puncture Repairs

Errors in surface preparation represent the most frequent cause of premature TPO membrane repair failure. Inadequate cleaning leaves contaminants that prevent proper adhesion between patching materials and the existing membrane. Rushed cleaning processes often miss embedded dirt, oil residues, or deteriorated membrane particles that create weak bonding zones.

Using the wrong type of primer also makes the problem worse when contractors skip this critical step or apply primer to damp surfaces, resulting in compromised chemical bonds that fail within months of initial TPO roof patching work.

Application mistakes during the repair process create vulnerabilities that lead to recurring leaks. Undersized patches that don’t provide enough overlap around puncture edges allow water in at weaker points where thermal expansion occurs. Poor adhesion techniques, including applying the wrong amount of pressure during bonding or incorrect temperature control during heat welding, create air pockets and incomplete seals.

Edge sealing failures represent another common issue where contractors neglect proper seam treatment around a patch. These TPO seam repair oversights allow moisture in that gradually undermines the entire single-ply roof repair, requiring expensive rework and potential damage throughout surrounding areas of the membrane that requires replacement.

When to Call Professionals vs. Making DIY Repair Attempts

Complex TPO roof puncture repair scenarios require professional expertise, particularly when damage involves multiple membrane layers, damage to the roof deck, or compromised insulation systems. Commercial buildings present additional safety hazards that exceed typical property owner capabilities, including significant heights and specialized equipment requirements.

Many professional contractors possess liability insurance coverage and have safety protocols essential for handling single-ply roof repair on commercial structures. Roofing material warranties also favor professional installation, as these types of guarantees typically require a certified contractor to be involved for TPO membrane repair work.

Simple surface punctures on accessible low-slope areas may allow property owner intervention using basic TPO roof patching techniques. Small holes from minor debris or equipment damage can often be addressed with temporary repair materials until a professional assessment occurs.

DIY attempts should never involve complicated heat welding machines or structural modifications, as improper technique can make damage significantly worse. Property owners attempting basic commercial roof leak repair must prioritize personal safety through proper fall protection and recognize the limitations of temporary solutions compared to professional TPO seam repair methods that provide long-term performance and warranty protection.

Preventive Maintenance Tips to Avoid Future TPO Roof Punctures

Regular inspection schedules form the cornerstone of effective puncture prevention for TPO membrane systems. Monthly visual inspections should focus on identifying potential hazards such as loose equipment, deteriorating roof accessories, or debris accumulation that could lead to membrane damage. Professional quarterly inspections can detect early signs of membrane stress, seam deterioration, or surface wear that precede puncture incidents. Seasonal inspections following severe weather events help identify storm damage before minor issues require extensive TPO roof puncture repair interventions.

Protective measures during routine building maintenance prevent accidental punctures that commonly occur during HVAC servicing, equipment installations, or general roof access activities. Establishing designated walkways with protective padding reduces foot traffic damage across the single-ply roof system. Installing equipment pads properly distributes weight equally, which could otherwise concentrate pressure points, leading to membrane failure. Training maintenance personnel on proper TPO membrane handling prevents tool damage and ensures that routine commercial roof leak repair needs remain minimal through careful prevention practices rather than reactive TPO roof patching requirements.

Expert TPO Roof Puncture Repair in Pittsburgh

If you’re dealing with TPO roof puncture damage, remember that quick, professional repairs are crucial to prevent further damage to your property. McClellands Contracting and Roofing, LLC specializes in both minor and extensive TPO roof puncture repairs. We understand the complexities of TPO membrane repair, ensuring we use the right materials and techniques to deliver durable and effective solutions.

Don’t let a small puncture turn into a big problem. Whether it’s a simple patch or a comprehensive repair involving heat welding, trust your local experts. Call McClellands Contracting and Roofing, LLC today at (412) 353-5660 to schedule an inspection and get your roof back in perfect condition.